Brief introduction of Impact crusher

The impact crusher is also called impact crusher.

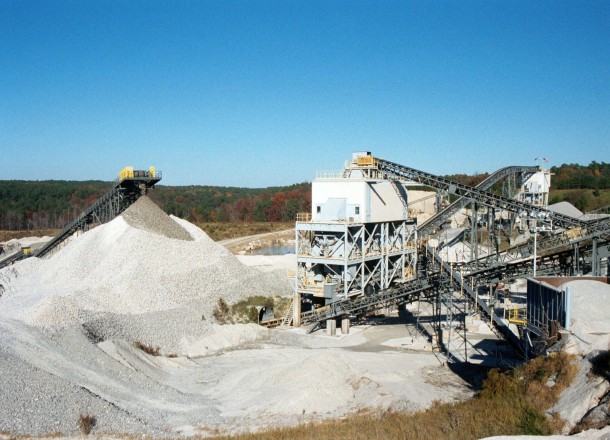

It is mainly used for metallurgy, chemical industry, building materials, hydropower and other materials that often require relocation operations, especially for mobile stone operations such as highways, railways, and hydropower projects. It can be processed according to the raw materials.

Different types, scales and finished material requirements adopt multiple configuration forms.

Working principle of Impact crusher

The impact crusher is a crushing machine that uses impact energy to crush materials. When the machine is working, driven by the motor, the rotor rotates at a high speed. When the material enters the impact area of the blower, it hits and breaks with the blower on the rotor, and then is thrown to the counterattack device to break again, and then bounce off the counterattack liner. Return to the hammer action area to re-crush. This process is repeated. The material enters the first, second, and third impact chambers from large to small, and is repeatedly crushed until the material is crushed to the required particle size and discharged from the discharge port.

The stone falls directly into the high-speed rotating turntable from the upper part of the machine; under the action of high-speed centrifugal force, it collides with another part of the flying rocks around the turntable in an umbrella-like manner to produce high-speed collision and high-density crushing. A vortex motion is formed between the turntable and the casing, causing multiple blows and smashes.