1.What’s the DRI?

Direct reduced iron (DRI) is a type of alternative iron made by heating iron ore, mill scale pellet or concentrated iron powder so that the oxygen and carbon burns off while the temperature is kept below iron's melting point. Direct-reduced iron is also known as sponge iron and is sold as briquettes, lumps, or pellets. It is typically used in smaller scale steel mills to enhance the condition of the steel that is manufactured.

During the reduction process in the production of direct reduced iron, either coal or a special gas — commonly containing a combination of carbon monoxide and hydrogen — is used. This mixture functions as a reducing agent and facilitates the decrease in the iron's oxygen and carbon content. The result is a type of iron that is 90-97% pure, containing only minuscule amounts of carbon and other impurities.

In the modern era, direct reduced iron is considered an alternative method of making iron. The process of crafting iron via the direct-reduction route has a distinct advantage over the more traditional, blast furnace mode of production. Not only is the resulting iron more plentiful in total iron content, but it entails a much cheaper production process than the operation of a large blast furnace.

2.The raw material

The raw material to produce DRI is Iron ore, mill scale, or concentrated iron powder which in Fine pellet or Lumps shape.

3.The chemical reactions of DRI production

The chemical reactions involved in the direct reduction of iron are the following:

With H2 (Gas Based)

3Fe2O3 + H2 → 2Fe3O4 + H2O

Fe3O4 + H2 → 3 FeO + H2O

FeO + H2 → Fe + H2O

With CO (Coal Based)

3Fe2O3 + CO →2Fe3O4 + CO

Fe3O4 + CO → 3 FeO + CO2

FeO + CO → Fe + CO2

With Solid Carbon in reaction

CO2 + C → 2CO

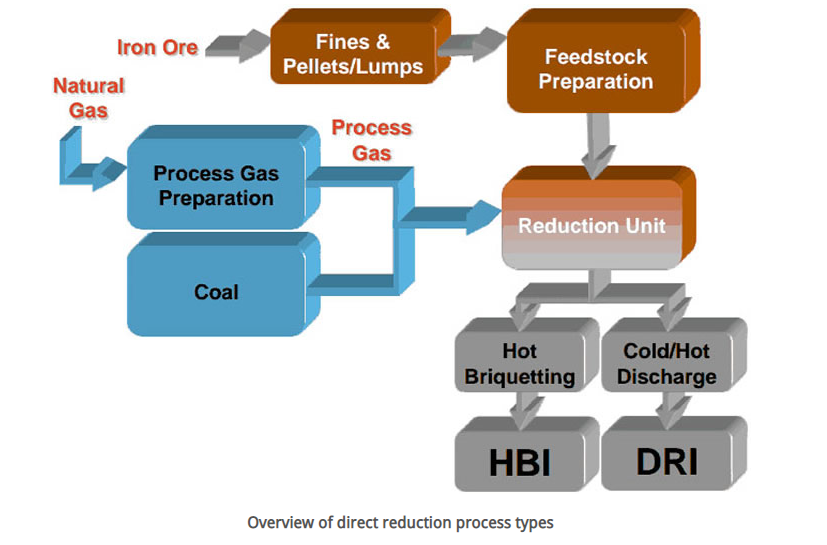

4.Direct reduction processes

There are several processes for direct reduction of iron ore:

-- gas-based rotary kiln furnace processes

-- coal based rotary kiln furnaces

Generic illustrations of the types of process are shown in the graphics below.

Our company is professional of Coal based DRI plant. Which use coal as the reduction agent, and mixed with iron ore or concentrated iron powder to produce the DRI.